Color coated plate in the production, handling and use of the process will inevitably bump, resulting in product damage, affect the normal use. In order to ensure the normal use of the product, here is a brief introduction to the causes and solutions of the surface scratch problem of the color coated plate.

Introduction to the basic knowledge of surface scratch problem of color coated roll

1. Overview

Color coated plate in the production, handling and use of the process will inevitably bump, resulting in product damage, affect the normal use. In order to ensure the normal use of the product, here is a brief introduction to the causes and solutions of the surface scratch problem of the color coated plate.

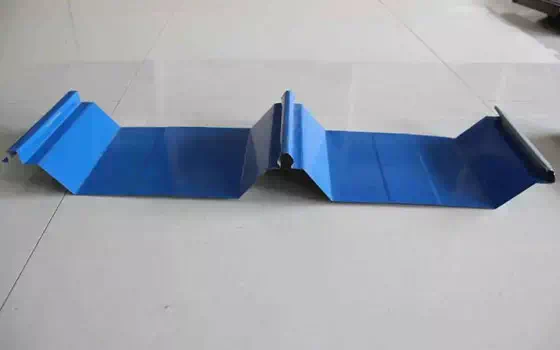

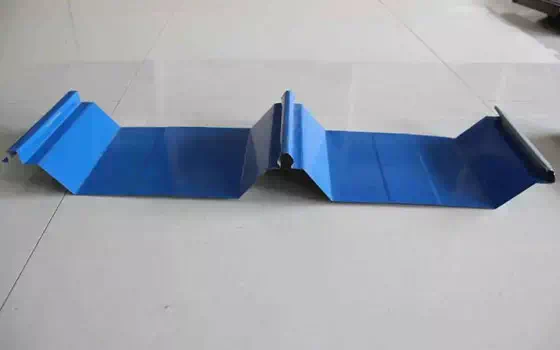

Surface scratch is a kind of surface defect in the production of color coated plate, which not only affects the appearance of the color coated product, but also reduces the corrosion resistance of the color coated product. It can be divided into raw material scratches and production process scratches according to the source.

2. Scratch on the surface of raw materials

Raw material surface scratch refers to the quality defect of the substrate during the production of galvanizing. When the scratched substrate is used to produce the color coated plate, the surface of the produced color coated plate is easy to produce color difference or even leakage of coating quality defects.

Specific solution: The control measures are to check the production quality in the previous process and prevent the raw material substrate with scratches from entering the factory.

3. scratches produced in the production process

1. There are foreign body scratches on the surface of the inlet and outlet guide plates, and the defects are located on the back of the steel plate. The main cause of the problem is that there are foreign bodies on the surface of the guide plates.

Specific solutions: regularly check the guide wear, repair, adjust; Reinforce the loose guide screws in time and remove foreign bodies on the surface of the guide plate in time.

2. The spray pipe is scratched, the defect is located on the back of the steel plate, the main reason for the problem is that the tension is too small, and the lower surface of the strip steel is in contact with the nozzle.

Specific solution: appropriately increase the strip tension of the cleaning section.

3. Extrusion roll scratch, the defect part is located on the front and back of the steel plate, the main reason for the problem is that there are foreign bodies on the surface of the roller or extrusion roll bearing stuck.

Specific solution: Remove the foreign matter on the surface of the roller, adjust the extrusion roll or bearing.

4.S roll scratch, the defect is located on the front and back of the steel plate, the main reason for the problem is that there are foreign bodies on the surface of the roller, the tension in the furnace body and the tension of the outlet loop are too large, resulting in the slip of S roll.

Specific solution: Remove the foreign matter on the surface of the roller, adjust the outlet looper and the tension control in the furnace.

5. Curing furnace scratch, the defect part is located in the front and back of the steel plate, the main reason for the problem is that the tension control in the curing furnace is not appropriate, the tension is too small, the steel plate sag scratch the back, the tension is too large when the production of thin material, the front of the furnace scratch.

Specific solution: adjust the tension control, control the overhang position of the strip steel.