Dear customers, here to introduce to you the quality products we provide - hot dip galvanized steel plate (GI plate). The production process of hot dip galvanized steel plate (GI plate) is rigorous and fine.

Product description provided by supplier

Dear customers, here to introduce to you the quality products we provide - hot dip galvanized steel plate (GI plate).

The production process of hot dip galvanized steel plate (GI plate) is rigorous and fine. First of all, the raw material selected is a strictly screened all-hard steel plate. These steel plates need to undergo a professional pickling process before being put into production. In this link, by using a specific concentration and proportion of acidic solution, the surface of the steel plate is comprehensively and carefully cleaned, which can effectively remove all kinds of impurities, oil and oxide on the surface of the steel plate, ensure that the surface of the steel plate is highly clean, and lay a solid foundation for the subsequent processing process.

After finishing the pickling treatment, the steel plate needs to be rolled. In this process, with the help of advanced rolling equipment and precise operating technology, the appropriate pressure and deformation amount are applied to the steel plate, so that it meets strict quality standards in terms of thickness, flatness and mechanical properties. After rolling, the steel plate not only has better dimensional accuracy and surface quality, but also its internal organizational structure has been further optimized.

Next, the critical galvanizing process. After pickling and rolling process, high quality all-hard steel plates are slowly passed through carefully maintained and tightly controlled zinc pans. In this environment filled with zinc liquid, the surface of the steel plate will be evenly coated with a zinc film. This layer of zinc film is closely combined with the steel substrate to form a unique hot-dip galvanized steel plate (GI plate).

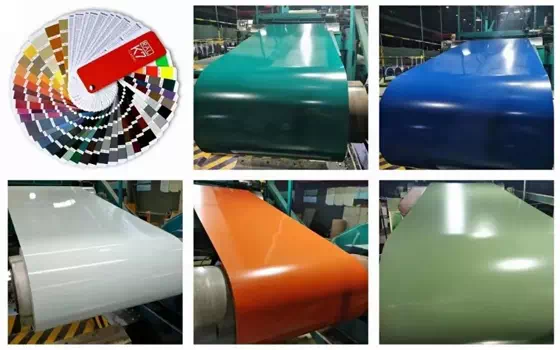

It is worth mentioning that because of the special physical and chemical properties of zinc itself, hot dip galvanized steel plate (GI plate) has many excellent properties. One of the most prominent is its excellent corrosion resistance. In a variety of complex environmental conditions, whether it is humid air, acid and alkaline substances erosion, or long-term outdoor exposure, zinc film can effectively protect the steel plate matrix from corrosion, greatly extending the service life of the product. At the same time, the zinc film also gives the product good paintability. This means that in practical applications, users can easily apply a variety of protective or decorative materials such as coatings and paints on the surface of galvanized steel plates to meet different needs. In addition, the hot-dip galvanized steel plate (GI plate) also has good machinability, whether it is cutting, welding, bending or stamping and other processing processes, can be easily dealt with, providing a broad space for the diversification of product applications.

Under normal circumstances, the hot-dip galvanized steel sheet and galvanized steel coil remain basically the same in terms of production process and specifications. This is because they all need to follow strict quality control systems and standardized production processes to ensure stable and reliable product performance and quality. In the production process, every link has been carefully designed and monitored, from the inspection of raw materials to the factory inspection of finished products, there are professional technicians to check the whole process, to ensure that each batch of products are in line with the relevant national standards and industry norms.

In order to meet the individual needs of different customers, we provide a full range of services in the customization of products. You can flexibly customize key parameters such as thickness, width, length, zinc layer thickness, execution standard and material according to your specific requirements. Whether you need steel sheets of a specific thickness for building structures, sheets of a specific width and length for special industrial designs, or zinc thickness for higher corrosion protection requirements, we can tailor the production to your exact needs.

If you are interested in our hot dip galvanized sheet (GI sheet), or have any questions or needs, please feel free to call us. We have a professional customer service team to provide you with 24 hours online service. Whether you are in the busy working hours during the day, or in the middle of the night to encounter emergency problems, we will be happy to serve you, timely answer your questions, to provide you with the best quality products and the most intimate service. Look forward to establishing long-term and stable cooperative relationship with you!

Product Name | Galvanized Steel Sheet (GI sheet) |

Width | 600-1500mm | Thickness | 0.12~6.00mm or as you request |

Length | 1000mm-12000mm or as your request | Tolerance | Thickness& Width:+/-0.02mm |

Zinc coating | 20-600g/m2 | Technique | Cold rolled or hot rolled |

Standard | GB / ASTM/JIS/AISI |

Grade | Q195,Q235,Q235B,Q345,Q345B |

SGCC, DX51D/ DX52D, SGCC,DX51D+Z/ DX52D+Z |

S280GD+Z, S350GD+Z |

SGCH,JIS G3302, ASTM A653 |

Spangle | Zero Spangle,Small Spangle,Regular Spangle,Big Spangle |

Hardness | Soft hard(<60),medium hard(HRB60-85),full hard(HRB85-95) |