Hot-rolled galvanized steel in the steel structure industry is mainly used for light steel structure houses and workshops, the main building skeleton are galvanized cold-formed steel, mainly C steel, Z steel, floor bearing plate and steel gutter manufacturing, thickness specifications are mainly 1.5-3.5mm.

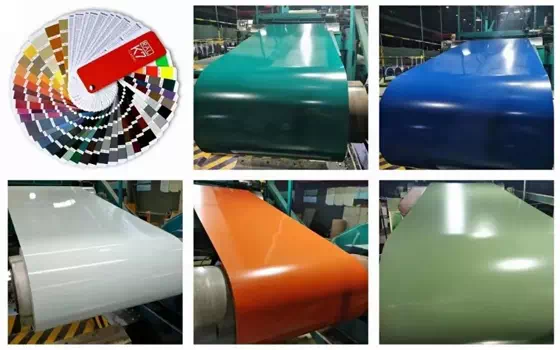

Hot-rolled galvanized steel in the steel structure industry is mainly used for light steel structure houses and workshops, the main building skeleton are galvanized cold-formed steel, mainly C steel, Z steel, floor bearing plate and steel gutter manufacturing, thickness specifications are mainly 1.5-3.5mm. Due to the light weight of steel structure building, high strength, beautiful shape, fast construction, less pollution, good wind resistance and seismic performance, it is an environmentally friendly "green building materials". In the developed countries, the use of steel structures such as plants and residential buildings has become the trend of building development, and the construction of steel structures in China is still in its infancy, and has great potential for development and scenting. According to the data in Taiwan, the use ratio of color coated plate and hot substrate galvanizing in construction is generally 5:1. Based on this calculation, the demand for hot-base galvanized sheet in China is about 600,000 tons. Because there is no production capacity of hot-rolled galvanized sheet in China, and imported products are far from meeting the market demand, the largest use of steel strip galvanized sheet produced by small galvanizing plants on the market at present, subject to production conditions and process technology restrictions, its products can not meet the needs of the market in terms of surface quality, control of galvanizing amount, corrosion resistance and mechanical properties. Compared with the original traditional storage containers, steel silos have the advantages of fast construction speed, good air tightness, high strength, small footprint, low cost, novel structure, beautiful appearance and so on. More than 80% of the steel for the production of granary is the thickness of 1.0-1.4mm, the width of 495mm hot rolled galvanized steel strip (2.5-4mm accounted for 75%), the material Q215-235, the amount of galvanized > 275 g/m2. Urban and industrial sewage treatment system of the sewage treatment tank mainly use 4.0mm galvanized sheet. The hot-rolled galvanized sheet in the highway guardrail is 3.0X480 galvanized sheet strip, the material is Q235. According to the forecast of the transportation planning department, in the next ten years, the average annual national highway built more than 2,000 kilometers, the required galvanized sheet is 136,000 tons, considering the renewal and maintenance of natural loss and accidental loss, it is expected that the annual construction of the highway needs more than 150,000 tons of galvanized sheet. The manufacture of the outer shell, inner shell, top and bottom plate of the passenger car requires 1.0-3.0mm hot-rolled or cold-rolled galvanized sheet. Hot-rolled galvanized sheet instead of cold-rolled sheet simplifies the process, speeds up the manufacturing cycle of the vehicle, and extends the service life of the vehicle. The average consumption of hot-rolled galvanized sheet per passenger car is 15 tons, of which 1-2.75mm is 4.5 tons. The national annual bus manufacturing capacity of about 10,000 vehicles, is expected to need about 45,000 tons of hot-rolled galvanized sheet. The amount of automobile coated steel plate in developed countries has accounted for more than 60% of the amount of sheet metal, and China's automobile industry has developed rapidly in recent years. It is an inevitable trend that the coating plate is widely used as the automobile body covering to improve the anti-corrosion performance. From the perspective of the use of galvanized sheet in automobiles, its use specifications are more and the amount is relatively large, mainly used in the bottom plate of the car, various beams, beam strengthening plates, supports, brackets and connecting plates. Due to the use of hidden parts, the surface quality and deep drawing performance requirements are not high, so some parts can be replaced by hot substrate galvanized sheet processing, automotive consumption of hot galvanized sheet specifications are mainly 1.5-3.0mm. Instead of cold-rolled galvanized sheet At present, domestic galvanizing manufacturers more than 1.2mm galvanized production of about 12-140,000 tons/year, according to relevant experts, cold-rolled galvanized sheet and hot galvanized sheet in the use of performance is little difference, and hot galvanized sheet has a significant cost advantage. In theory, hot substrate galvanizing can completely replace cold substrate galvanizing products.