At present, the types of coatings used for color coated steel plates include polyester coating (PE), fluorocarbon coating (PVDF), silicon modified coating (SMP), high weather resistant coating (HDP), acrylic acid coating, polyurethane coating (PU), plastisol coating (PVC), etc.Polyester (PE, polyest

At present, the types of coatings used for color coated steel plates include polyester coating (PE), fluorocarbon coating (PVDF), silicon modified coating (SMP), high weather resistant coating (HDP), acrylic acid coating, polyurethane coating (PU), plastisol coating (PVC), etc.

Polyester (PE, polyester):

PE coating has good adhesion to materials. Color coated steel plate is easy to process and form, cheap, and has many products, and there is a wide choice of color and luster. Under direct exposure in general environment, its anti-corrosion life can be as long as 7-8 years, but its service life will be relatively reduced in an industrial environments or seriously polluted areas, but the polyester coating is not ideal for UV resistance and film pulverization resistance Therefore, the use of PE coating still needs to be limited. It is generally used in areas with less air pollution or products requiring multiple molding and processing.

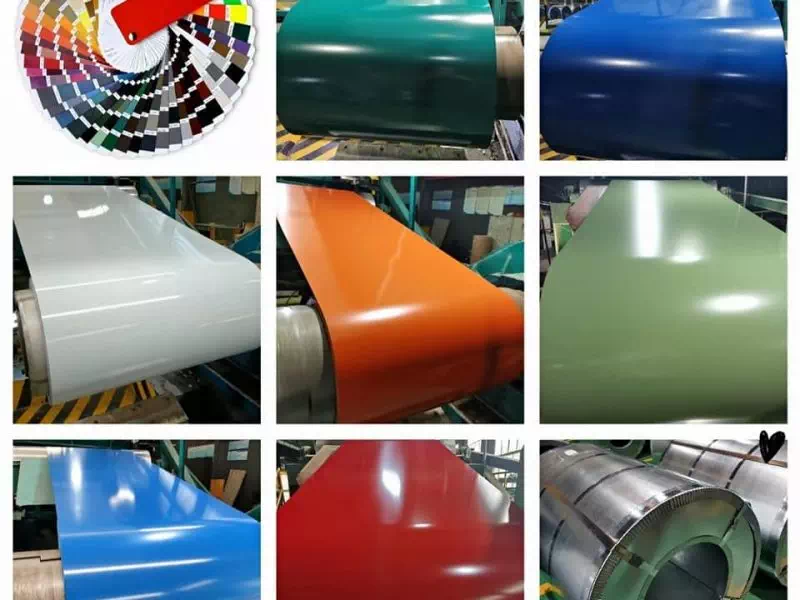

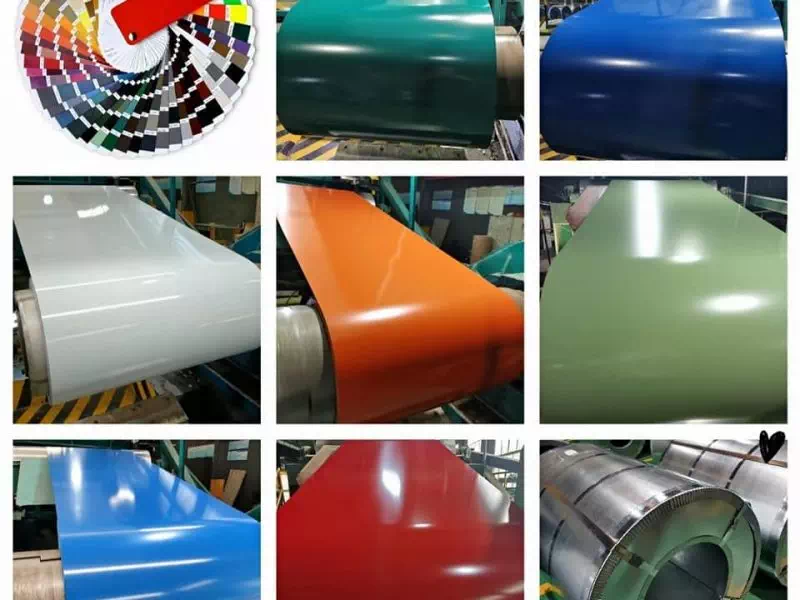

General paint classification of color steel sheet/coil

Silicon modified polyester (SMP):

Because polyester contains the active group – OH / – COOH, it is easy to react with other macromolecules and polymers. In order to improve the sunlight resistance and Pulverization of PE, silicone resin with excellent color retention and heat resistance is used for denaturation reaction, and the denaturation ratio with PE can be between 5% – 50%. SMP provides better durability of steel plate, and its anti-corrosion life can be as long as lo-12 years. Of course, its price is higher than that of PE, but because of Silicone the adhesion and processing formability of resin to materials are not ideal, so SMP color coated steel plate is not suitable for occasions requiring multiple molding processing, and most of it is used for the roof and exterior wall of buildings.

High weather resistant polyester (HDP, high durable polymer):

General paint classification of color steel sheet/coil

For the shortcomings of PE and SMP, British hydro company (now acquired by BASF) In early 2000, Becker of Sweden and others developed HDP polyester coating with weather resistance of 60-80% of PVDF coating, which is better than ordinary silicon modified polyester coating, and its outdoor weather resistance reaches 15 years. During the synthesis of high weather-resistant polyester resin, a monomer containing cyclohexane structure is used to achieve the balance of flexibility, weather resistance, and cost of tree fat, and aromatic free polyols and polybasic acids are used to reduce the absorption of UV light by the resin and achieve the high weather resistance of the coating. Ultraviolet absorber and steric barrier amine (HALS) are added to the coating formula to improve the weather resistance of the paint film. The high weather-resistant polyester coil coating has been recognized by the market abroad, and the cost performance of the coating is very outstanding.

General paint classification of color steel sheet/coil

Polyvinylidene fluoride PVDF:

Due to the strong bond energy between the chemical bonds of PVDF, the coating has very good corrosion resistance and color retention. In the color-coated steel plate coatings used in the construction industry, it is the most advanced product with large molecular weight and direct bond structure. Therefore, in addition to the chemical resistance, the mechanical properties, UV resistance, and heat resistance are also outstanding. In the general environment, its anti-corrosion performance is very good The corrosion life can be as long as 20-25 years. In recent years, fluorine-containing resin copolymerized with chlorotrifluoroethylene and vinyl ester monomer has become popular in China, which is widely used in building exterior walls and metal plates. Due to the use of an easily hydrolyzed vinyl ester monomer and the content of fluorine is about 30% lower than PVDF, its weather resistance is different from PVDF. The fluorocarbon coating is produced by contains. The amount shall not be less than 70% (others are acrylic resin).

Polyurethane

General paint classification of color steel sheet/coil

A new type of topcoat developed in recent years, with excellent comprehensive performance and high price, is being popularized.

Acrylic resin:

Resin type hardness bending corrosion resistance weather resistance cost thickness requirements / um

Polyester Superior Good Good Good Superior 20

Acrylic resin Superior General Good Good Inferior 20

Silicon modified polyester Good General Good Superior Good 20

PVC sole General Superior Superior Good Inferior 200

PVDF resin General Superior Superior Superior Inferior 25

High weather Good Superior Good Superior Good 20

resistant polyester

It has good comprehensive performance and high price, and is only used in specific fields (such as containers).

Fig. performance comparison of different coatings

For the selection of primer, there are two most important factors. One is to consider the adhesion of primer, topcoat and substrate. The other is that primer provides most of the corrosion resistance of coating. From this point of view, epoxy resin is the best choice. Polyurethane primer can also be selected if flexibility and UV resistance are considered.

For the back coating, the most correct choice is to select two layers of structure, i.e. one layer of back primer and one layer of back finish, if the color coated steel plate is single plate. The primer is of the same variety as the front, and one layer of light color (such as white) is selected for the finish If the color coated steel plate is a composite or sandwich plate, it is OK to apply a layer of epoxy resin with excellent adhesion and corrosion resistance on the back.

General paint classification of color steel sheet/coil

At present, there are still many functional color coated steel plates, such as antibacterial color coating, antistatic color coating, thermal insulation color coating, self-cleaning color coating, etc. the development of these products is to meet the special needs of users, but sometimes they can not take into account other properties of color coated products. Therefore, users must be clear about their real needs when selecting functional color-coated steel plates.