Jun 30, 2023

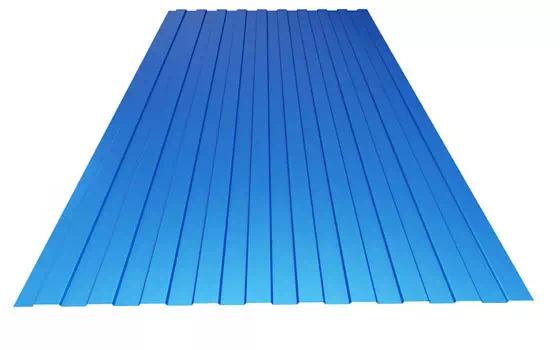

Color coated board knowledge

If the color coated steel plate is used as a composite or sandwich board, the back is coated with a layer of epoxy resin with excellent adhesion and corrosion resistance.

Get a free quote quickly!

Jun 30, 2023

If the color coated steel plate is used as a composite or sandwich board, the back is coated with a layer of epoxy resin with excellent adhesion and corrosion resistance.

There are many factors to consider in the choice of coating, which mainly includes the type of coating, coating thickness, coating color and coating gloss. In addition, sometimes it is necessary to consider the requirements of the primer and back coating of the coating. At present, the types of coatings used for color coated steel plates are polyester coating (PE), fluorocarbon coating (PVDF), silicon modified coating (SMP), high weather resistant coating (HDP), acrylic acid coating, polyurethane coating (PU), plastisol coating (PVC) and so on.

Common coating types

polyester

PE coating has good adhesion to the material, color coated steel plate is easy to process and form, cheap and many products, and the choice of color and luster is large. Polyester coating resistance to UV light and coating powder resistance, is not ideal, so the use of PE coating still need to be subject to some restrictions, generally used in areas where air pollution is not serious or need multiple molding processing products.

Applicable industry

Ordinary industrial plants and warehousing logistics warehouses do not corrod color plates themselves, and the corrosion resistance and anti-aging requirements of color plates are not high, and more consideration is given to the practicability and cost performance of plant construction

Silicon-modified polyester

Because polyester contains the active group OH/-COOH, it is easy to react with other polymers. In order to improve the sun resistance and pulverization property of PE, Silicone resin with excellent color retention and heat resistance is denatalized, and the denatalization ratio between 5%-50% and PE can be achieved by SMP, which provides better durability of the steel plate. Its anticorrosion life can be as long as 10-12 years, of course, its price is higher than PE, but because of the adhesion of Silicone resin to the material and the formability of processing is not ideal, SMP color coated steel sheet is not suitable for occasions where multiple molding processing is required, and most of it is used for building roofs and external walls.

High weather resistant polyester

For the shortcomings of PE and SMP, HYDRO in the UK (now acquired by BASF) and BECKER in Sweden developed HDP polyester coatings that can reach 60-80% weather resistance of PVDF coatings in early 2000, which is better than ordinary silicon modified polyester coatings, and its outdoor weather resistance reaches 15 years. In the synthesis of high weather resistance polyester resin, monomer containing cyclohexane structure is used to achieve the balance of flexibility, weather resistance and cost of the resin, and the use of non-aromatic polyols and polyacids to reduce the absorption of UV light by the resin to achieve high weather resistance of the paint.

Uv absorbent and steric hindrance amines (HALS) were added to the coating formulation to improve the weatherability of the coating film. High weather resistant polyester coil coating has been recognized by the market in foreign countries, and the cost performance of the coating is very outstanding.

Applicable industry

Metallurgy, power industry non-ferrous metal smelters (copper, zinc, aluminum, lead, etc.) is the most challenging life of the color plate, steel plants, power plants, etc., will also produce corrosive media, the color plate corrosion resistance requirements are higher.

PVC Plastisol

PVC resin has good water resistance and chemical resistance, generally with high solid part coating, its coating thickness between l00-300μm, can provide smooth PVC coating or light embossing treatment for embossing coating; Because the PVC coating is a thermoplastic resin, it has a high film thickness and can provide good protection for the steel plate. But PVC heat resistance is weak. In the early days, it was used more in Europe, but due to its relatively poor environmental properties, it is now used less and less.

Fluorocarbon PVDF

Due to the chemical bond of PVDF and chemical bond, there is a strong bond energy, so the coating has very good corrosion resistance and color retention, in the construction industry with color coated steel coating, is one of the highest products, and the molecular weight is large and straight bond structure, so in addition to chemical resistance, mechanical properties, UV resistance and heat resistance are also very prominent. In the general environment, its anti-corrosion life can reach 20-25 years. In recent years, fluorinated resin with trifluorinated vinyl chloride and vinyl ester monomer has become popular in China, which is widely used in building exterior walls and metal plates. Due to the use of easily hydrolyzed vinyl ester monomer and fluorine content about 30% lower than PVDF, its weather resistance is compared with PVDF, and there is a certain gap. The fluorocarbon coating produced by Baosteel has a PVDF content of no less than 70%(the others are acrylic acid resin).

Applicable industry

Chemical industry products have volatile characteristics, easy to produce acidic or alkaline corrosive volatile substances, easy to form dew attached to the surface of the color plate after water, corrosion of the coating of the color plate, and may further corrosion to the zinc layer and even steel plate.

02 Performance comparison table of different coatings

For the choice of primer, there are two most important factors, one is to consider the primer and top paint and substrate adhesion, and the other is that the primer provides most of the corrosion resistance of the coating. From this point of view, epoxy resin is the only choice. If you consider flexibility, consider UV resistance, you can also choose polyurethane primer. For the back coating, the most correct choice is that if the color coated steel plate is used as a single board, choose a two-layer structure, that is, a layer of back primer and a layer of back finish. The primer and the front are of the same variety, and the top coat is a light color (such as white) of polyester. If the color coated steel plate is used as a composite or sandwich board, the back is coated with a layer of epoxy resin with excellent adhesion and corrosion resistance.

03 Coating glossiness selection

Gloss level is not a coating performance indicator, like color, it is only a representation. In fact, coatings (coatings) are relatively easy to achieve high gloss. However, the high reflectivity of the high-gloss surface dazzling sunlight during the day will cause light pollution (many now do not use glass curtain walls because of light pollution), in addition, the high-gloss surface friction coefficient is small, easy to slip, in the roof construction, easy to bring security risks; The aging of color coated steel plate in outdoor use is the first indication of loss of light, if it needs to be repaired, it is easy to distinguish between old and new steel plates, resulting in poor appearance; If the back paint is high gloss, it is easy to produce halo when there is light in the room and cause visual fatigue. Therefore, under normal circumstances, color coated steel plates for construction are used in low gloss (30-40 degrees).

04 Coating thickness selection

From the microscopic point of view, the coating is a long and short organization. Water in the air, corrosive media (chloride ions, etc.) will invade through the weak part of the coating, causing subfilm corrosion, and then the coating bubbles and spalling. In addition, even with the same coating thickness, the secondary coating is denser than the primary coating. According to foreign reports and related corrosion test results, the front coating above 20μm can effectively prevent the intrusion of corrosive media, because the anti-corrosion mechanism of primer and top paint is different, not only to specify the total film thickness, but also require the thickness of primer (" 5μm) and top paint (" 15μm), only in this way, in order to ensure that the corrosion resistance of different parts of the color coated steel plate is balanced.

PVDF products require thicker coatings. Because to provide a longer service life guarantee. The requirements for the back coating depend on the use, and the sandwich board is only required to have a binder primer. The formed steel plate is also required to be coated with two layers due to the indoor corrosion environment. Thickness of at least 10μm.

Choice of coating color (highlight!)

The choice of color is mainly to consider the match with the surrounding environment and the owner's hobbies, but from the point of view of the use of technology, the choice of light color paint pigments, inorganic coatings with superior durability can be selected (such as titanium dioxide, etc.), and the heat reflection ability of the coating is strong (reflection coefficient is twice that of the dark paint), the temperature of the summer coating itself is relatively low. This is beneficial for the extension of coating life. In addition, even if the coating is discolored or powdered, the contrast between the light color film and the original color is small after the change, and the impact on the appearance is not large. The deep colors (especially the more bright colors) are mostly organic colors, which are easy to fade when exposed to ultraviolet light, and change color in the shortest 3 months. According to relevant test data, when the outside temperature is the highest at noon in summer, the white surface temperature is 10 degrees lower than the blue surface, and 19 degrees lower than the black surface. Different colors reflect sunlight differently.

05 Color reflectance reflection effect

For the color coated steel plate, the thermal expansion rate of the coating and the steel plate is usually different, especially the linear expansion coefficient of the metal substrate and the organic coating is different. When the ambient temperature changes, the expansion or contraction stress will occur at the interface between the substrate and the coating, and the coating will crack if it is not properly released. Baosteel has done 8 years of exposure test of the same paint variety, the same paint supplier and different colors in Hainan, and the results also confirmed that the light color paint discoloration is small.

06 Luster color difference original thickness now thickness

In addition, here to explain two misunderstanding of the current choice in the domestic market:

First, there is a large number of white primers in China. The purpose of using white primer is to reduce the thickness of the top paint, because the normal anticorrosive primer used in construction is yellow-green (so there is strontium chromate pigment), and there must be enough thickness of the top paint to have good hiding power. In this way, the corrosion resistance is very dangerous, first of all, the corrosion resistance of the primer is poor, and the top paint is greatly reduced to less than 10 microns. This color coated steel plate looks bright, and it will not take two years to produce corrosion in different places (incision, bending processing, under the film, etc.).

Second, the same project using different manufacturers, different batches of color coated steel plate, in the construction seems to be the same color, but after several years of sunlight exposure, different coating of different manufacturers of color change trend is different, resulting in serious color difference, such examples are too many. Even if the products of the same supplier, it is strongly recommended that the same project be ordered once, because different batch numbers may use different paint suppliers' products, increasing the possibility of color difference.

Reasonable selection of materials can not only improve the service life of buildings, but also reduce costs, so as to truly achieve environmental friendliness and resource saving.