1. Carbon of Chemical Elements

The role of carbon in steel is a double-edged sword. With the increase of carbon content, the yield point and tensile strength of the material gradually increased, but the formability and impact resistance decreased. Therefore, the carbon content needs to be adjusted for different material uses.

Forms solid solution structures and increases the strength of the steel, such as ferritic and austenitic structures, all of which are dissolved in carbon;

The formation of carbide structure can improve the hardness and wear resistance of steel. For example, cementite, Fe3C, is a carbide structure.

Therefore, the higher the carbon content in the steel, the higher the strength and hardness of the steel, but the lower the ductility and toughness; on the contrary, the lower the carbon content, the higher the plasticity and toughness of the steel, and the lower the strength and hardness.

Therefore, the carbon content level determines the use of the steel: low carbon steel (carbon content < 0.25%), usually used as profiles and stamping materials; medium carbon steel (carbon content < 0.6%), generally used as mechanical parts; high carbon Steel (>0.7% carbon content), commonly used as tools, knives and dies.

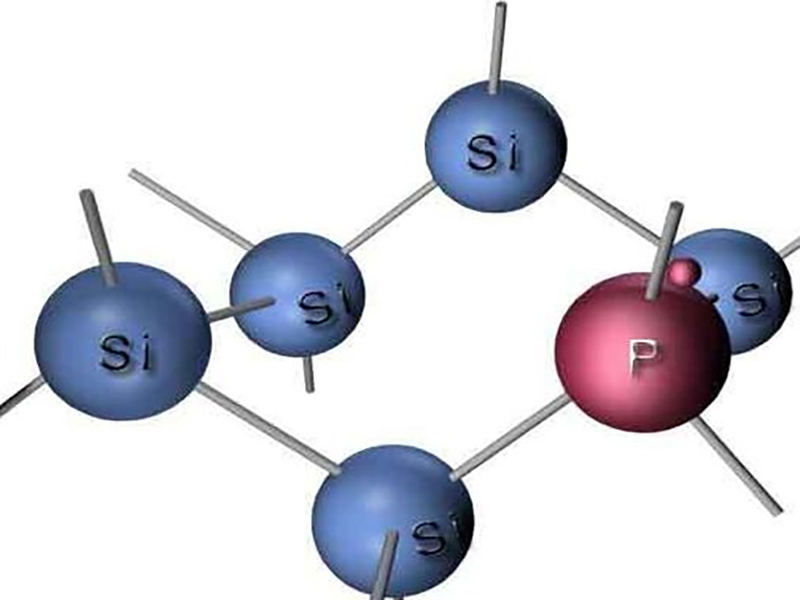

2. Silicon of Chemical Elements

Silicon is added as a reducing agent and deoxidizer in the steelmaking process, so killed steel will contain 0.15-0.30% silicon. When the silicon content in the steel exceeds 0.50-0.60%, silicon is used as an alloying element.

Silicon element can significantly improve the elastic limit, yield point and tensile strength of steel, so it is widely used in spring steels such as 65Mn and 82B containing 0.15-0.37% silicon. Adding 1.0-1.2% silicon to quenched and tempered structural steel can increase the strength of the steel by 15-20%;

the combination of silicon with molybdenum, tungsten, chromium, etc. has the effect of improving corrosion resistance and oxidation resistance, and can be used in manufacturing Heat-resistant steel; low-carbon steel containing 1.0-4.0% silicon, with extremely high magnetic permeability, used in the electrical industry to manufacture silicon steel sheets.

Of course, silicon is not harmless, it can degrade the weldability of steel.

3. Manganese of Chemical Elements

In the steelmaking process, manganese is a good deoxidizer and desulfurizer. The content of manganese in steel is generally 0.30-0.50%. When carbon steel is added more than 0.70%, it is regarded as “manganese steel”.

Compared with ordinary steel, it not only has sufficient toughness, but also has higher strength and hardness, which can improve the hardenability of steel and improve the hot workability of steel. For example, the yield point of 16Mn steel is 40% higher than that of A3 steel. Steel containing 11-14% manganese has extremely high wear resistance and is used in excavator buckets, ball mill liners, etc.

High levels of manganese also have disadvantages. When the manganese content is high, the steel has obvious temper brittleness phenomenon; manganese has the effect of promoting grain growth, and attention should be paid during the heat treatment process; when the mass fraction of manganese exceeds 1%, the welding performance of the steel will be reduced.

4. Sulphur of Chemical Elements

Sulfur comes from steelmaking ore and fuel coke. It is a harmful element in steel.

Sulfur is present in steel in the form of iron sulfide (FES). FES and Fe form compounds with low melting point (985 ℃), and the hot working temperature of steel is generally 1150-1200 ℃. Therefore, during hot working of steel, FES compounds will melt prematurely and crack the workpiece, a phenomenon called “hot brittleness”. The higher the sulfur content, the more serious the thermal embrittlement. Therefore, it is necessary to control the sulfur content in steel.

High quality steel s < 0.02-0.03%, high quality steel s < 0.03-0.045%, ordinary steel s < 0.055% – 0.07%. In individual cases, it is necessary to add sulfur. For example, adding 0.08-0.20% sulfur to steel can improve the machinability, which is usually called free cutting steel.

Sulfur is also harmful to weldability and reduces corrosion resistance.

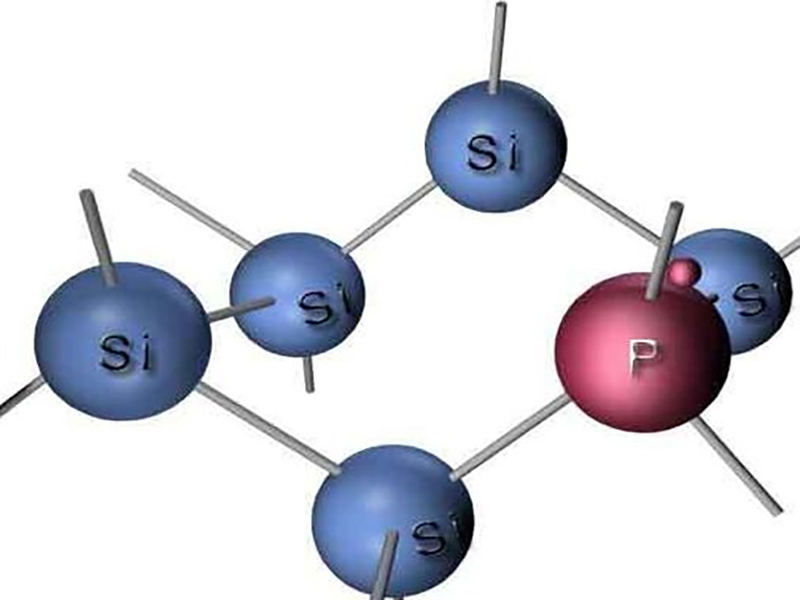

5. Phosphorus of Chemical Elements

Phosphorus is brought into steel by ore. generally speaking, phosphorus is also a harmful element. Although phosphorus can improve the strength and hardness of steel, it will lead to a significant decrease in plasticity and impact toughness. Especially at low temperature, the steel becomes significantly brittle, which is called “cold embrittlement”.

Cold brittleness will reduce the cold workability and weldability of steel. The higher the phosphorus content, the greater the cold brittleness, so the more strict the control of phosphorus content in steel. High grade high-quality steel: P < 0.025%; High quality steel: P < 0.04%; Ordinary steel: P < 0.085%.

6. Oxygen of Chemical Elements

Oxygen is a harmful element in steel. It naturally enters the steel in the steelmaking process. Although manganese, silicon, iron and aluminum are deoxidized at the end of the steelmaking process, they cannot be completely removed. Oxygen in the form of FeO, MnO, SiO2, Al2O3 and other inclusions in steel will reduce the strength and plasticity of steel. In particular, it has a serious impact on fatigue strength and impact toughness.

7. Nitrogen of Chemical Elements

The ability of ferrite to dissolve nitrogen is very low. When supersaturated nitrogen is dissolved in steel, nitrogen precipitation in the form of nitride will occur after long-time storage or heating to 200-300 ℃, which will improve the hardness and strength of steel, reduce plasticity and aging Adding Al, Ti or V into molten steel for nitrogen fixation to fix nitrogen in AlN, tin or VN can eliminate the aging tendency.

8. Chromium of Chemical Elements

In structural steel and tool steel, chromium can significantly improve the strength, hardness and wear resistance, so that the steel has good oxidation resistance and corrosion resistance. It is an important alloy element of stainless steel and heat-resistant steel; It can also improve the hardenability of steel and is an important alloy element.

However, chromium will also increase the brittleness transition temperature of steel, increase the tempering brittleness of steel, and cause unnecessary trouble in the processing process.

Nickel can increase the strength of steel while maintaining good plasticity and toughness. Nickel has high resistance to acid and alkali corrosion, rust and high temperature heat resistance. However, because nickel is a relatively scarce resource, other alloy elements should be used to replace nickel chromium steel.

10. Molybdenum of Chemical Elements

Molybdenum can refine the grain of steel, improve hardenability and thermal strength, and maintain sufficient strength and creep resistance at high temperature (long-term stress and deformation at high temperature, called creep). Molybdenum is added to structural steel to improve mechanical properties. It can also inhibit the embrittlement of alloy steel due to fire. Adding molybdenum to tool steel can improve redness.

11. Titanium of Chemical Elements

Titanium is a strong deoxidizer in steel. It can compact the internal structure of the steel and refine the grain force; Reduce aging sensitivity and cold brittleness. Improve welding performance. Intergranular corrosion can be avoided by adding appropriate titanium to Cr18Ni9 Austenitic stainless steel.

12. Vanadium of Chemical Elements

Vanadium is an excellent deoxidizer for steel. Adding 0.5% vanadium to steel can refine microstructure and grain, and improve strength and toughness. The carbides formed by vanadium and carbon can improve the hydrogen corrosion resistance under high temperature and high pressure.

13. Tungsten of Chemical Elements

Tungsten has a high melting point and a large ratio. It is its own alloy element. Tungsten and carbon form tungsten carbide with high hardness and wear resistance. Adding tungsten into tool steel can significantly improve red hardness and thermal strength, and can be used for cutting tools and forging dies.

14. Niobium of Chemical Elements

Niobium can refine the grain, reduce the superheat sensitivity and temper brittleness of the steel, and improve the strength, but the plasticity and toughness decrease. Adding niobium to ordinary low alloy steel can improve the resistance to atmospheric corrosion and hydrogen, nitrogen and ammonia corrosion at high temperature. Niobium improves weldability. Adding niobium to austenitic stainless steel can prevent intergranular corrosion.

15. Cobalt of Chemical Elements

Cobalt is a rare and precious metal, which is mainly used in special steels and alloys, such as heat-resistant steels and magnetic materials.

16. Copper of Chemical Elements

Copper can improve strength and toughness, especially atmospheric corrosion. The disadvantage is that it is easy to produce thermal brittleness during hot working, and the plasticity decreases significantly when the copper content exceeds 0.5%. When the copper content is less than 0.50%, it has no effect on the weldability.

17. Aluminum of Chemical Elements

Aluminum is a commonly used deoxidizer in steel. Adding small amounts of aluminum to steels can refine grains and improve impact toughness, such as 08Al steels used for deep drawing sheets. Aluminum also has anti-oxidative and anti-corrosion properties.

The combination of aluminum, chromium and silicon can significantly improve the high temperature peeling performance and high temperature corrosion resistance of steel. The disadvantage of aluminum is that it affects the hot workability, weldability and machinability of steel.

18. Boron of Chemical Elements

Adding a small amount of boron to steel can improve the compactness and hot rolling properties of the steel and increase the strength.

Rare earth elements refer to the 15 lanthanides with atomic numbers 57-71 in the periodic table. These elements are all metals, but their oxides are similar to “earth”, so they are often referred to as rare earths.

Adding rare earths to steel can change the composition, shape, distribution and properties of inclusions in steel, thereby improving various properties of steel, such as toughness, weldability and cold workability. Rare earths are added to plowshare steel to improve wear resistance.