Steel grid is a versatile and durable building material used in a wide variety of industries and applications. Their diversity is not only expressed in materials and manufacturing processes, but also in various ways of classification. In this article, we will introduce the classification of steel gr

Steel grid is a versatile and durable building material used in a wide variety of industries and applications. Their diversity is not only expressed in materials and manufacturing processes, but also in various ways of classification. In this article, we will introduce the classification of steel grid in detail in order to better understand its application in different scenarios.

1. Material classification

1.1 Carbon steel grille plate: Carbon steel grille plate is one of the most common types, usually made of carbon steel, with strength and corrosion resistance.

1.2 Stainless steel grille plate: Stainless steel grille plate is made of stainless steel, has excellent corrosion resistance, suitable for harsh environments.

1.3. Aluminum alloy grille plate: Aluminum alloy grille plate is lightweight and corrosion resistant, often used in light applications and decorative projects.

1.4 Alloy steel grille plates: Alloy steel grille plates are usually made of alloy steel to meet the requirements of special applications, such as high temperature or high pressure environments.

2. Manufacturing process classification

2.1. Pressure welded steel grid plate: pressure welded steel grid plate is the transverse rod and vertical rod through the pressure welding process firmly connected, with excellent load-bearing capacity.

2.2. Insert steel grid plate: The insert steel grid plate is to insert the transverse rod into the hole of the longitudinal rod to form an economic and practical grille.

3. Surface treatment classification

3.1. Hot-dip galvanized grid plate: The surface of the hot-dip galvanized grid plate is plated with a layer of zinc, which improves its corrosion resistance and is often used in outdoor and humid environments.

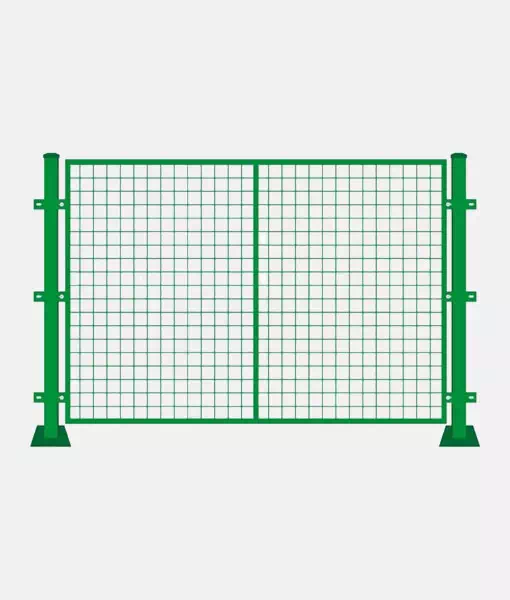

3.2. Coated grille plate: The coated grille plate is usually coated with a layer of paint by spraying or dipping to increase surface protection and aesthetics.

4. Opening type classification

4.1. Flat open grille panels: Flat open grille panels have smooth surfaces and are suitable for walking areas and decorative projects.

4.2. Toothed open grille plate: The toothed open grille plate has a toothed notch to provide good anti-slip performance, suitable for slopes and slippery ground.

4.3. Type I open grille plate: Type I open grille plate transverse rod and longitudinal rod is type I, suitable for large span bearing places.

4.4. U-shaped open grille plate: the horizontal rod and vertical rod of the U-shaped open grille plate are U-shaped, which has a large drainage capacity and is suitable for drainage system.

5. Classification of application fields

5.1. Construction applications: Steel grating plates are used in the construction industry for stairs, platforms, railings and ventilation grates.

5.2. Industrial applications: commonly used in industry for factory floor, mechanical equipment support and cargo pallets.

5.3. Transportation applications: Steel grilles are used for roads and sidewalks on Bridges, highways, airports and docks.

5.4. Energy industry applications: Used in power plants, oil fields, solar power stations and other energy facilities.

5.5. Water treatment engineering applications: used in sewage treatment plants, pond covers, water parks and swimming pools.

5.6. Food processing applications: Used in food processing equipment, chimney, kitchen drainage system.