Q235 welded steel pipe is carbon structural steel (GB/700-2006) Q235 welded steel pipe, also known as welded pipe, is made of steel plate or strip after curling forming welded steel pipe.

Q235 welded steel pipe is carbon structural steel (GB/700-2006) Q235 welded steel pipe, also known as welded pipe, is made of steel plate or strip after curling forming welded steel pipe. Welded steel pipe production process is simple, high production efficiency, variety specifications, less equipment, but the general strength is lower than seamless steel pipe.

Q235 Welded steel pipe is used for conveying low pressure fluid. General welding pipe Q195A, Q215A, Q235A steel manufacturing. It can also be made of other mild steels which are easy to weld. Water pressure, bending, flattening and other experiments should be carried out on the steel pipe, which has certain requirements on the surface quality. Usually, the delivery length is 4-10m, and the delivery length is usually fixed (or multiple) feet. The specification of the welded pipe is expressed by the nominal diameter (mm or inch). The nominal diameter is different from the actual diameter. The welded pipe has two kinds of ordinary steel pipe and thickened steel pipe according to the specified wall thickness, and the steel pipe has two kinds of thread and no thread according to the form of the pipe end.

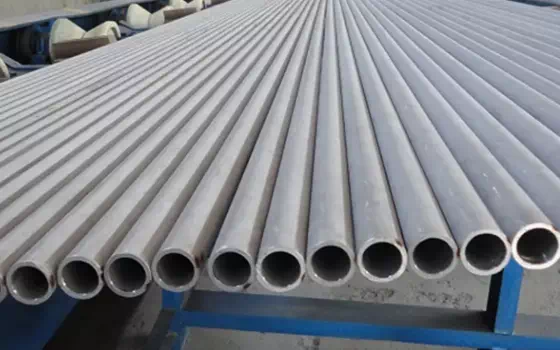

Welded steel pipe is divided into straight welded pipe and spiral welded pipe according to the form of weld.

Classification by production method: Process classification - arc welded pipe, resistance welded pipe, (high frequency, low frequency) gas welded pipe, furnace welded pipe. Straight welded pipe production process is simple, high production efficiency, low cost, rapid development. The strength of spiral welded pipe is generally higher than that of straight welded pipe, and welded pipe with larger diameter can be produced with narrower billet, and welded pipe with different diameter can also be produced with billet of the same width. But compared with the same length of straight seam pipe, the weld length is increased by 30~100%, and the production speed is lower.