The metal nickel, with its unique chemical and physical properties, occupies an indispensable position in the industrial field. Chemically, it is represented as Ni and is located in the 28th position in the periodic table.

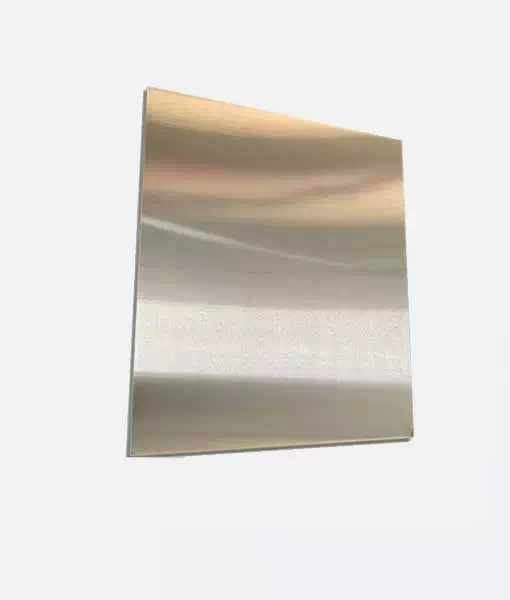

The metal nickel, with its unique chemical and physical properties, occupies an indispensable position in the industrial field. Chemically, it is represented as Ni and is located in the 28th position in the periodic table. Nickel has a density of 8.902 grams per cubic centimeter, which indicates that it is relatively heavy. In addition, it has a melting point of 1,453 degrees Celsius and a boiling point of 2,732 degrees Celsius, which reveals the stability of nickel at high temperatures. In appearance, nickel presents a similar silver color, giving people a bright visual feeling. At low temperatures, nickel exhibits good strength and ductility, which makes it very useful in machining and manufacturing. At room temperature, when exposed to humid air, the surface of nickel will form a dense oxide film, which can effectively prevent further oxidation of nickel, thereby protecting the material from erosion. In addition, nickel is also easily synthesized with other metals as alloys, which further enhances its range of applications.

Main application areas of nickel

As an important industrial metal, nickel has a wide range of applications, involving steel, machinery, construction and chemical industry and other fields. Specifically, the application of nickel can be summarized as follows:

Metal material: Nickel is a key component in the manufacture of stainless steel, heat-resistant alloy steel and various other alloys. Due to their excellent properties, these alloys are widely used in building structures, automobile manufacturing, aerospace and other fields.

Electroplating industry: In the plating process, nickel is used to form a durable and corrosion-resistant coating on the surface of steel and other metal materials, which is far more resistant to corrosion than traditional galvanized coating.

Catalyst: In the petrochemical industry, especially in the hydrogenation process, nickel acts as a catalyst to accelerate chemical reactions and improve production efficiency.

Chemical power supply: Nickel is a key ingredient in the manufacture of nickel-metal hydride and nickel-cadmium batteries, which are widely used in portable electronic devices and power tools.

Pigments and dyes: Nickel is also used to make certain types of pigments and dyes, and plays a role in the production of new materials such as ceramics and ferrites.

According to the different production materials, nickel can be divided into two categories: primary nickel and recycled nickel. Primary nickel is mainly derived from nickel ore in nature, while recycled nickel is obtained by recycling nickel-containing waste. In primary nickel, we can find electrolytic nickel, nickel iron and nickel salts and other forms. Electrolytic nickel in accordance with the provisions of China's national standard GB/T6516-2010, can be divided into Ni9999, Ni9996, Ni9990, Ni9950, Ni9920 five grades according to purity. Nickel-iron, also known as nickel-bearing pig iron, is an alloy of nickel and iron, mainly made of laterite nickel ore through fire smelting and sintering. According to the different nickel content, nickel iron can be divided into high nickel pig iron, medium nickel pig iron and low nickel pig iron, their nickel metal content is about 5% to 30%.

In general, nickel is an extremely important industrial metal, both in terms of physical and chemical properties and application scope, and its diverse uses and forms make it play a pivotal role in modern industry.