Hot dip plating, often referred to simply as hot plating, is a unique plating technique. The key to this technique is to completely immerse the plated metal material in other liquid metals or alloys with a relatively low melting point.

Hot dip plating, often referred to simply as hot plating, is a unique plating technique. The key to this technique is to completely immerse the plated metal material in other liquid metals or alloys with a relatively low melting point. In this way, a protective coating can be formed on the surface of the material being plated.

Take iron and steel materials as an example, when it is hot galvanized, it will show some basic characteristics. First, an alloy layer is formed between the steel substrate and the zinc coating. The formation of this alloy layer is due to the interaction of steel and zinc at high temperatures, forming a new substance. Secondly, when the steel part is lifted from the molten metal zinc liquid, a layer of molten metal zinc is attached to the surface of this alloy layer. This layer of molten metal zinc will form a layer of metal zinc coating after cooling and solidification. This coating can not only provide protection for the steel, but also enhance its corrosion and wear resistance, thereby extending its service life.

Iron and steel material plays an important role in the hot dip plating process, as the base material, its properties directly affect the effect of the coating. Therefore, when selecting the coated metal, it is necessary to ensure that the melting point of the metal is much lower than the melting point of steel to ensure the smooth process of hot dip plating.

Among the many steels suitable for hot-dip plating, low-silicon boiling steel is considered to be the ideal choice. According to the American Metal manual, steel suitable for hot dip galvanizing should have a low silicon content, the specific requirement is that the silicon content (wSi) is less than 0.05%. This is because the silicon element will affect the formation and quality of the coating during the hot dip plating process.

In domestic research and practice, Class B steel in Q235 steel is considered to be the most suitable for hot-dip galvanizing treatment. After hot galvanizing, the steel can form a tight, continuous and uniform intermetallic compound structure, which significantly improves the corrosion resistance and appearance quality of the steel.

However, with the wide application of continuous cast steel technology, hot dip galvanizing is facing new challenges. The silicon content of this new steel grade usually exceeds 0.05%, which brings difficulties to the traditional hot-dip galvanizing process. For workpieces that are not low carbon steel or whose silicon content is not in the ideal range, hot dip galvanizing work does become more complicated. However, hot-dip galvanizing of such materials can still be achieved by using other process methods.

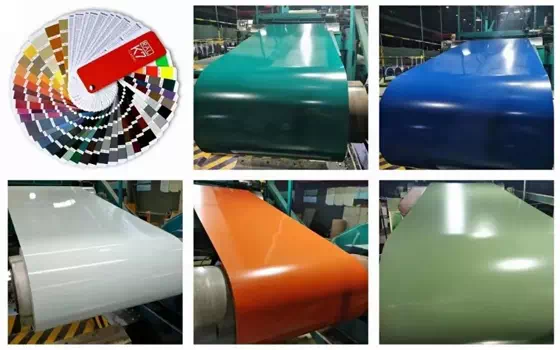

In the field of hot dip plating, commonly used coating metals include zinc, aluminum, tin and lead. Each of these metals has its own characteristics, but zinc stands out because of its relatively low cost, good plating properties, and excellent corrosion resistance. The melting point of zinc is 419.5℃, which is much lower than the melting point of steel, which enables it to be successfully coated on the surface of steel during the hot dip plating process. As a low value corrosion protection coating, zinc is widely used to protect steel parts from atmospheric corrosion, and is often used to improve the appearance of the decorative effect of products.

In general, iron and steel material is the main substrate of hot dip plating, and its properties and composition have an important influence on the selection of coated metal and hot dip plating process. In the selection of coated metal, in addition to considering the melting point factor, it is also necessary to consider the cost, performance and process requirements to ensure that the ideal coating effect is obtained.