The thin steel plate is immersed in the dissolved zinc bath so that its surface adheres to a thin steel plate. It is mainly produced by continuous galvanizing process, that is, the coiled steel plate is continuously immersed in the plating groove dissolved with zinc to make galvanized steel plate.

The thin steel plate is immersed in the dissolved zinc bath so that its surface adheres to a thin steel plate. It is mainly produced by continuous galvanizing process, that is, the coiled steel plate is continuously immersed in the plating groove dissolved with zinc to make galvanized steel plate. This steel plate is also made by hot immersion, but after the groove, it is immediately heated to about 500 ℃, so that it generates an alloy film of zinc and iron. This galvanized coil has good coating adhesion and weld ability.

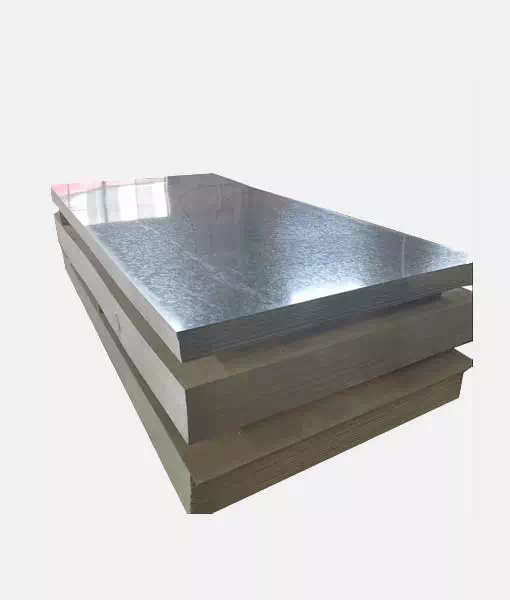

Galvanized coil can be divided into hot rolled galvanized coil and cold rolled galvanized coil, they are mainly used in the construction of household appliances, car containers, transportation and other fields, especially steel structure construction, automobile manufacturing, steel warehouse manufacturing and other industries their characteristics are mainly: strong corrosion resistance, good surface quality, economic and practical.

| Thickness | 0.105- 4MM |

| Width | 600 - 1250MM |

| Length | As require |

| Zinc Coating | Z30 - 600g//m2 |

| ID of Coil | 508/610MM |

| Surface Structure | Regular spangle,Minimum spangle, Zero spangle, Big spangle |

| HRB | Soft Hard (<60),Medium Hard (60-85), Full Hard (85-95) |

| Surface Treatment | Oiled (O), Chromium (C),Phosphating (P), Spinpass |

| Standard Seaworthy Export Packing | Dust-proof kraft sheet, iron packing, Angle protective, packing belt |

| Coil Weight | 3-5 Tons |

| Standard | ASTM-A653; JIS G3302; EN10147;etc |

| Payment Terms | T/T, LC, Western Union, Paypal, O/A, DP |

| Regular Order | 25 tons or one container, for less quantity, to contact with us for details.

|

Galvanized coil defined as a carbon steel sheet coated with zinc on both sides. A zinc coating is one of the most effective and economical methods of protecting bare steel from a corroding environment. The zinc not only serves as a barrier

between the steel and the environment, it will sacrifce itself to protect the underlying steel sheet.

Galvanization or galvanizing is the process of applying a protective zinc coating to steel or iron, to prevent rusting.The size of crystallites (grains) in galvanized coatings is a visible and aesthetic feature, known as "spangle".

With the cold rolled steel of different strength and thickness as substrate, it is produced through applying the zine coat on both faces by hot dip process.