WisCO and Baosteel took the lead in introducing color-coated steel plate production lines. Since then, China has begun to apply domestic color coated laminated plates to industrial buildings. With the rapid development of the application technology of color coated molded steel plate, the application range is expanding and the amount is increasing.

Corrugated steel plates were produced in the United States in the 1930s. In the early 1980s, WisCO and Baosteel took the lead in introducing color-coated steel plate production lines. Since then, China has begun to apply domestic color coated laminated plates to industrial buildings. With the rapid development of the application technology of color coated molded steel plate, the application range is expanding and the amount is increasing.

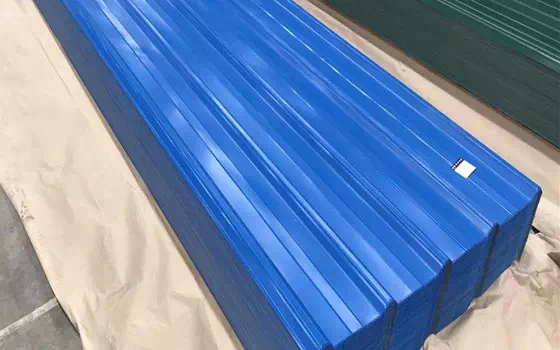

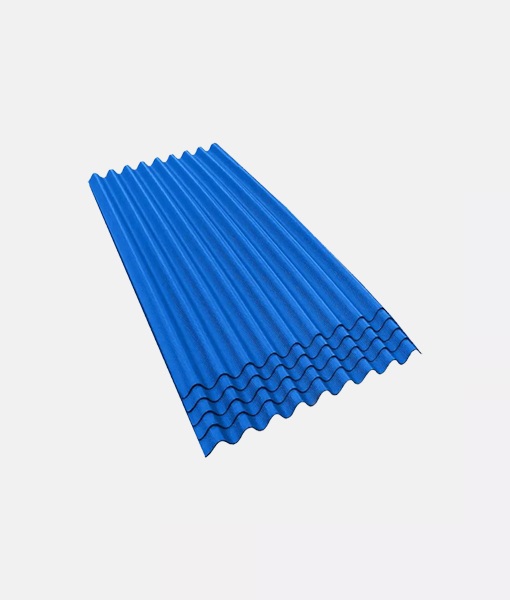

Classification of corrugated steel plates.

Molded steel plates are usually classified in a variety of ways according to the application site, plate wave height, lap structure and material. There are several common classification methods:.

(1) According to the application of classification - divided into roof board, wall board, floor and ceiling board. In the process of use, the color steel plate is also used as a wall decoration board, and the architectural decoration effect is relatively novel and unique.

(2) According to wave height classification - divided into high wave board (wave height ≥70mm), medium wave board (wave height < 70mm) and low wave boards (wave height less than 30mm)

(3) According to the classification of substrate materials - divided into hot-dip galvanized substrate, hot-dip galvanized substrate, hot-dip galvanized aluminum substrate.

(4) According to the construction method of the plate joint, it is classified into lap, undercut, buckling structure, etc. Among them, the bottom cut type medium and high corrugated cardboard is suitable for making roofing panels with high waterproof requirements. The floor is made of lapped medium and high wave galvanized sheet. Overlapping low-wave plates should be used as wall panels.

Characteristics of corrugated steel plate.

Product performance: color plate thickness is 0.2mm~ 1.0mm.

Effective width: 608mm, 760mm, 820mm, 900mm, 950mm, 960mm, 1025mm, etc

Corrugated steel plate for use.

(1) Beautiful and novel shape, rich color, decorative strong, flexible combination, can express different expressions.

Architectural style.

(2) waterproof agent light weight (6 ~ 10kg/m2), high strength (yield strength 250 ~ 550MPa), skin stiffness, good seismic performance.

(3) The factory products are of high quality.

(4) The construction and installation is convenient, reducing the workload of installation and transportation, and shortening the construction period.

(5) Molded steel plate is an environmentally friendly building material that can be recycled. The popularization and application of molded steel plate is in line with the policy of sustainable development of China's national economy.

(6) A single material is more expensive and less durable than concrete or masonry enclosure materials.