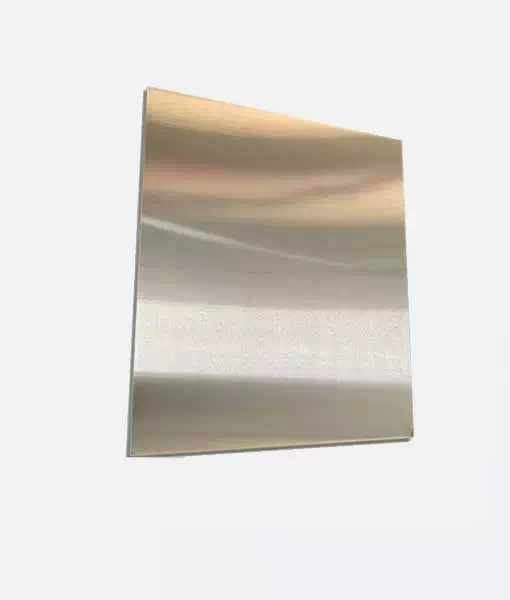

Wear-resistant alloy steel is a kind of steel with special properties, which is mainly used for impact loads under wear conditions. Its main characteristics are high strength, hardness, toughness and wear resistance under wear conditions. Strictly speaking, wear-resistant manganese steel also belongs to wear-resistant alloy steel, considering that the wear-resistant material industry at home and abroad often lists wear-resistant manganese steel as a single class.

Definition and classification of wear-resistant alloy steel

Wear-resistant alloy steel refers to steel with other elements purposefully added to meet specific performance requirements. These elements are called alloying elements, such as chromium (Cr), nickel (Ni), molybdenum (Mo), copper (Cu), silicon (Si), manganese (Mn), vanadium (V), titanium (Ti), rare earth (Re), tungsten (W), boron (B), etc. In a specific environment, even some harmful elements can also be called alloying elements, such as sulfur (S), phosphorus (P) and so on. According to the total amount of alloying elements, wear-resistant alloy steel can be divided into five categories: austenitic manganese steel, medium chromium steel, low alloy steel and graphite steel, which are suitable for different industrial and mining conditions.

Second, wear-resistant low-alloy steel definition, main varieties, properties and applications

In wear-resistant alloy steel, the total amount of alloying elements (Fe, C and harmful elements and hidden elements) shall not be higher than 5%, which is called low alloy steel (5-10% for medium alloy steel, 10-15% for high manganese steel). The mechanical properties of low alloy steel, especially the hardness and toughness, can be adjusted in a wide range, and the strength, impact toughness and wear resistance can be comprehensively considered and matched according to different conditions of use. As long as the fracture is not caused by brittleness, its wear resistance increases with the increase of hardness.

Generally, low-alloy wear-resistant steel is known for its high strength and toughness and high hardness and toughness. Its strength and hardness are higher than those of wear-resistant manganese steel and can replace manganese steel in non-impact wear conditions. Its plasticity and toughness are higher than that of wear-resistant cast iron, and its service life is higher than that of wear-resistant cast iron under certain impact load wear conditions.

The main purpose of adding alloy elements is to improve hardenability, strength, toughness and wear resistance. The most common additions are Mo, Cr, Mn, Ni, and Si.

Third, the casting and welding properties of low-alloy martensitic wear-resistant steel are similar to other low-alloy steels, and the welding performance is poor when the carbon content is high. Low-alloy wear-resistant steels can be classified by heat treatment and carbon content.

1. Water quenching heat treatment alloy martensitic wear resistant steel: W(C)=0.2%-0.35% of the multi-component low alloy steel, after water quenching and tempering treatment, high hardness, good wear resistance, with good strength and toughness, not easy to deformation and fracture in use, widely used in excavators, loaders and tractors bucket teeth, track plate, small and medium-sized jaw plate, hammer, plate hammer and so on.

2. Oil quenching, air quenching heat treatment of low alloy martensitic wear-resistant steel: W(C)> 0.35% multi-component low alloy steel can be obtained by oil quenching (or air quenching) heat treatment and tempering treatment according to different alloy content, martensitic steel with good strength and toughness, high hardness and good wear resistance. However, the toughness of this kind of steel is lower than the aforementioned W(C)=0.20%-0.35% water quenched heat treatment of low-alloy martensitic steel, so its application must consider the impact load of the working condition.

Four. Positive heat treatment of low-alloy pearlite wear-resistant steel: W(C)=0.55%-0.9% of high-carbon chromium-manganese molybdenum steel, pearlite matrix can be obtained by normalizing and tempering heat treatment. Chromium-manganese pearlite wear-resisting steel has good toughness and impact fatigue resistance, and high work-hardening ability. And because it only contains less inexpensive alloying elements and does not need to undergo complex heat treatment, it has lower production costs.

Five. Application fields of different types of wear-resistant steel

High carbon chromium manganese molybdenum pearlite cast steel is used for certain impact load abrasive wear conditions, such as the hollow magic ball of E type coal mill and ball mill liner. The more typical grade is ZG85Cr2MnMo, ≥800MPa, ≥500MPa, ≥1%. The chemical composition and mechanical properties of representative high carbon chromium manganese molybdenum pearlite wear-resistant cast steel are shown in Table 7(omitted).

Table 8(omitted) and Table 9(omitted) are shown for the wear resistance comparison test of Cr-Mo pearlite wear-resistant steel lining plate with high manganese steel and Cr-Mo martensitic wear-resistant steel lining plate in φ2.7m molybdenum ball mill. It can be seen that the service life of chromium molybdenum pearlite wear-resistant steel lining plate is higher than that of high manganese steel, and lower than that of 555-601HBW chromium molybdenum martensite wear-resistant steel lining plate; Even if the pearlite steel liner has lower hardness but higher service life than 480°C tempered martensitic wear-resistant steel liner.

The wear resistance of carbon steel is mainly obtained by surface hardening. W(C)> 0.35% carbon steel, usually surface induction hardening or flame hardening; The wear resistance of low carbon steel can be improved by carburizing, nitriding or carbonitriding. With the increase of hardness, its wear resistance is also increased. In the wear-resistant carbon steel, W(C)=0.4%-0.70% carbon steel plays an important role, and the cast steel train wheel in the United States is made of W(C)=0.4%-0.70% carbon steel.

Cast graphite steel is ultra-high carbon eutectoid steel, after appropriate heat treatment, a part of the carbon is precipitated in the form of graphite, so it has the comprehensive properties of cast steel and cast iron. Due to the presence of free graphite, this steel is a structural material resistant to friction and wear. Graphite steel is mostly used in the manufacture of metallurgical rolls, such as rolls for primary rolling or rough rolling operations, because a small amount of graphite can improve the thermal cracking resistance of the roll and the resistance to oxidation sheet adhesion.