Welcome to Shandong Zhishang Steel Co., Ltd.

Get a free quote quickly!

FOB Reference Price: Get latest price

On the basis of galvanized coil, it is covered with color coating, which gives more colors to the product, and the colorful and beautiful surface makes it more widely used.

Payments (Enjoy encrypted and secure payments View details)

Payments (Enjoy encrypted and secure payments View details) Delivery Policy (Contact supplier to negotiate shipping details)

Delivery Policy (Contact supplier to negotiate shipping details) Return Policy (Eligible for returns and refunds View details)

Return Policy (Eligible for returns and refunds View details)Standard | PPGI:JIS G3303,GB/T 12754-1991;PPGL:ASTM A755/M,JIS G3322 |

Material | DX51D,DX52D,S350GD,S550GD |

Thickness | 0.12-3.0 mm |

Width | 20-1500 mm,Normal width is 914/1000/1219/1250/1500 mm |

Type of coating process | Front:double coated&double drying;Back:double coated&double drying;single coated&double drying; |

Coating Types | Top paint: PVDF, HDP, SMP, PE,PU; Primer paint: Polyurethance, Epoxy,PE, Back paint:epoxy,modified polyester |

Coil ID | 508 mm/610 mm |

Coil weight | 3-12 tons |

Packing | Export standard packing or according to customers' requirement. |

Shipment | Within10-15 workdays,25-30 days when the quantity beyond 1000 tons. |

Delivery term | 10—15 days after receive deposit |

Shipments terms | FOB CIF CFR all available |

It usually refers to ppgi coil, ppgi sheet and other steel products.

On the basis of galvanized coil, it is covered with color coating, which gives more colors to the product, and the colorful and beautiful surface makes it more widely used.

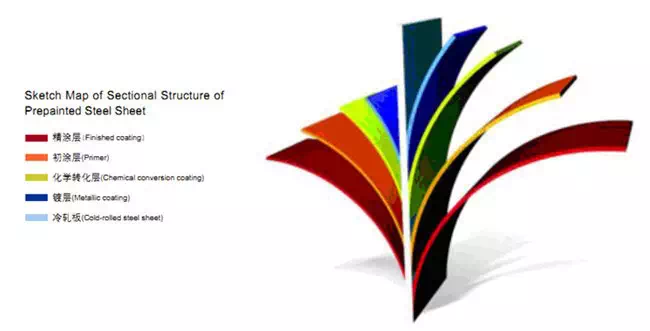

Color coated steel plate is a new type of strip pre-coating product that has developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, initial coating and fine coating on high-speed continuous unit. The coating quality is more uniform, more stable and more ideal than the quality of single piece spraying or brushing on the formed metal surface;

The color coated steel plate has excellent decoration, formability, corrosion resistance, strong coating adhesion, and can maintain novel color for a long time. Because the color coated steel plate can obtain good economic benefits such as steel instead of wood, efficient construction, energy saving, pollution prevention and so on, it has become an ideal material for manufacturing building plates today.

First. basic characteristics

1. Light weight: 10-14 kg/square meter, equivalent to 1/30 of the brick wall.

2. Heat insulation: thermal conductivity of core material: λ< =0.041w/mk.

3. High strength: can be used as ceiling envelope plate bearing, bending and compressive resistance; General houses do not use beams and columns.

4. Bright color: no need for surface decoration, the retention period of color galvanized steel anti-corrosion layer is 10-15 years.

5. Flexible and fast installation: the construction period can be shortened by more than 40%.

6. Oxygen index: (OI)32.0(Provincial fire product quality inspection station).

Two. the main types

The substrate of color steel plate is cold-rolled substrate, hot-dip galvanized substrate and electroplated zinc substrate. The types of coatings can be divided into polyester, silicon modified polyester, polydifluoroethylene and plastisol. The surface state of color steel plate can be divided into coated plate, embossing plate and printing plate, color steel plate is widely used in building home appliances and transportation and other industries, for the construction industry is mainly used for steel structure factory, airport, warehouse and refrigeration and other industrial and commercial buildings roof walls and doors, civil buildings using color steel plate less.

Different from plastic steel

The difference between it and plastic steel is that the composition of the material is different, and the magnet can suck.

Strictly speaking, plastic steel and color steel can not be well distinguished in metal characteristics and surface treatment, because they are much the same; Therefore, the market is mainly differentiated in terms of profile structure.

The magnet test

Because it is an ordinary carbon steel material, the magnet can be absorbed. In addition, it is added that stainless steel is the product of adding chromium (greater than or equal to 13%) on the basis of low carbon steel, so the magnet can not absorb.

Third. development trend

First. the use of high-quality substrate, the surface of the substrate, plate shape and dimensional accuracy requirements are getting higher and higher, outdoor use such as small zinc flower flat hot galvanized steel coil, zinc alloy hot plated steel coil without zinc flower flat hot galvanized steel coil and the rise of zinc alloy hot plated coil; Indoor use such as electric galvanized steel coil, film cold rolled sheet and aluminum sheet coil.

Second, improve the pretreatment process and pretreatment liquid, the number of equipment is small, the cost is low to become the mainstream process, and constantly improve the stability, corrosion resistance and environmental protection performance of the pretreatment liquid.

Third. focus on the development of new coatings, general polyester, polyvinylidene fluoride (PVDF) and plastisol improvement, to obtain super color reproducibility, UV resistance, sulfur dioxide resistance, improve corrosion resistance; Develop functional coatings that are resistant to pollution and heat absorption.

Fourth. the unit equipment is more perfect. Such as the use of new welding machine, new roller coating machine, improve the curing furnace, the configuration of advanced automatic instruments.

Fifth. because of the low cost of cold embossing than hot embossing, with beautiful, three-dimensional, high strength characteristics, so that cold embossing production technology has become a development trend.

Sixth. pay attention to the diversification, functionalization and high-grade of products, such as deep-drawing color coating board, "grapefruit skin" color coating board, anti-static color coating board, anti-pollution color coating board, high heat absorption color coating board.

Fourth. characteristics and performance

Color steel plate coating is cold-rolled steel plate, galvanized steel plate, surface chemical treatment after coating (roll coating) or composite organic film (PVC film, etc.), and then baked and cured products. Some people also call this product "pre-roll coated steel plate" and "plastic colored steel plate". Color plate products are produced in rolls by manufacturers on continuous production lines, so they are also called color coated steel plate rolls. Color steel plate not only has high mechanical strength of steel material, easy to form the performance, but also has a good decorative coating material and corrosion resistance. Color steel plate is an emerging material respected in today's world. With the progress of science and technology, the enhancement of environmental awareness, and the improvement of people's living standards, the color steel plate activity room is more and more showing a strong vitality and broad market prospects, and is favored by construction, home appliances, electrical and mechanical, transportation, interior decoration, office appliances and other industries.

The color steel plate activity room has the advantages of light weight, high strength, thermal insulation, beautiful and durable, and is a high-level building integrated with the decoration and installation fast. Color steel plate activity room construction clean, widely used in large-span workshop, warehouse, office building, villa, roof layer, air purification room, cold storage, shops, kiosks and temporary rooms. The weight of light color steel plate sandwich plate is less than 14KG, which can fully reduce the structural load and reduce the structural cost of the mobile house.

Easy to install

The characteristics of light weight, splicing installation and can be cut at will determine the simple installation of the active room, which can greatly improve the efficiency and save the construction period. The surface material and insulation material of the fireproof color steel sandwich board are non-combustible materials, which can fully meet the requirements of the fireproof code of the mobile room.

Durability

A variety of studies show that the wide use of more than 40 years abroad has confirmed that the shelf life of the color steel plate treated with special coating is 10-15 years, and the anti-corrosion coating is sprayed every 10 years, and the life of the mobile house plate can reach more than 35 years.

Pleasing to the eye

The clear lines of the color steel plate can be dozens of colors, which can meet the needs of any style of activity room building to achieve satisfactory results.

5. Composition and application

1. The substrate of color steel plate can be divided into cold-rolled substrate, hot-dip galvanized substrate and electroplated zinc substrate.

2. the coating types of color steel plate can be divided into: polyester, silicon modified polyester, poly difluoroethylene, plastic sol.

3. the color of the color steel plate can be divided into many types according to the user's requirements, such as orange, cream, deep sky blue, sea blue, crimson, brick red, ivory, porcelain blue and so on.

4. the surface state of the color steel plate can be divided into coating plate, embossing plate, printing plate.

5. the market use of color coated steel plate is mainly divided into three parts: construction, home appliances and transportation, of which the construction field accounts for the largest proportion, followed by the home appliance industry, and the transportation industry only accounts for a small part.

Construction color steel plate is generally hot-dip galvanized steel plate and hot-plated aluminum zinc steel plate as the substrate, mainly processed into corrugated board or with polyurethane composite sandwich board, used for the construction of steel structure factory, airport, warehouse, freezer and other industrial and commercial buildings roof, wall, door.

Home appliance color plate is generally galvanized and cold plate as the substrate, used for the production of refrigerators and large air conditioning systems, freezers, bread machines, furniture and so on.

The transportation industry generally uses electrogalvanized and cold plate as the substrate, mainly used in oil pan, automotive interior parts and so on

Q.What's your advantage?

A: Honest business with competitive price and professional service on export process.

Q. How I believe you?

A : We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

Q.Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately. if you are not pleased with our quality or service.

Q.Where are you? Can I visit you?

A: Sure,welcome to you visit our factory at any time.

Q.How about the delivery time?

A: Within 7-15 days after we confirm you requirement.

The company mainly deals in color-coated, galvanized, stainless steel pipes, stainless steel coils, stainless steel plates of various materials; hot-rolled series of rebar, medium and heavy plates, coils, I-beams, angle steels, channel steels, H-beams and other steel products and deep processing Service. (The company’s annual inventory is more than 50,000 tons).The company adheres to the concept of “integrity first, service-oriented”, relying on the strong strength of major domestic steel groups, exerting the company’s strong resource integration capabilities, and serving and satisfying the needs of customers both in China and at abroad.Additionally, Zhishang Steel also has a powerful and professional logistics distribution system, which can provide customers with efficient, fast and flexible logistics services at any time.Our business covers Southeast Asia, the Middle East, Africa, Australia, Europe, the United States and other countries.Looking forward to the future, in order to maintain in-depth and stable cooperation with customers both at home and abroad, all employees of Zhishang Steel will work harder to provide Better products and services to create more added value for customers.