Precision cold-rolled sheet is hot-rolled steel coil as raw material, after pickling to remove the oxide skin, cold continuous rolling, the finished product is rolled hard coil, because of the cold hardening caused by continuous cold deformation.

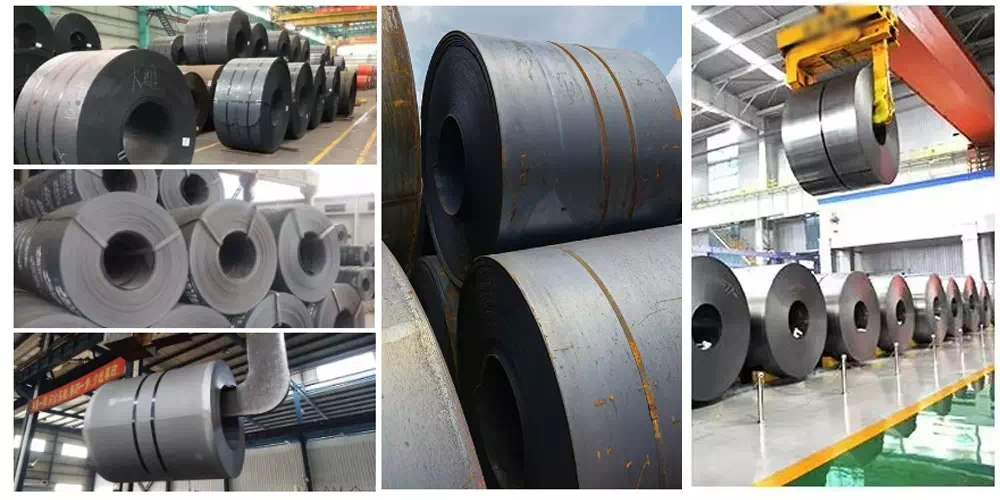

Product Name | Carbon Steel Coil |

Shape | Steel Coil |

Standard | ASTM, JIS, EN, GB |

Material | Q195, Q215, Q235, Q255, Q235B, Q355B, etc. |

Width | Customize |

Thickness | 0.2-80mm |

Thickness Classification | Thin plate, Medium plate, Thick plate, Extra thick plate |

Application | Bridges, boilers, shipbuilding, armor, automobiles, roofing and so on. |

Precision cold-rolled sheet is hot-rolled steel coil as raw material, after pickling to remove the oxide skin, cold continuous rolling, the finished product is rolled hard coil, because of the cold hardening caused by continuous cold deformation, the strength and hardness of the rolled hard coil increase, the toughness and plastic index decline, so the stamping performance will deteriorate, can only be used for simple deformation parts.

Because it has not been annealed, its hardness is very high (HRB greater than 90), the machining performance is very poor, and only a simple directional bending process of less than 90 degrees (perpendicular to the winding direction) can be carried out.

To put it simply, cold rolling is a process rolled out on the basis of hot rolled coil, generally speaking, it is a process of hot rolling - pickling - cold rolling.

Cold rolling is processed by hot rolled plate at room temperature, although the steel plate will also heat up during the processing process because of rolling, it is still called cold rolling. Because of the continuous cold rolling, the mechanical properties of cold rolling are poor and the hardness is too high. Must be annealed to restore its mechanical properties, not annealed called rolled hard roll. Rolled roll is generally used to do no bending, stretching products, less than 1.0 thickness rolled hard luck on both sides or four sides of the bend.

Cold rolling is the process of further rolling the material that has been hot rolled, pitted and oxidized at a temperature below the recrystallization temperature of the alloy with a press wheel to allow the material to recrystallize. After repeated cold pressing - recrystallization - annealing - cold pressing (repeated 2 ~ 3 times) process, the metal in the material changes at the molecular level (recrystallization), and the physical properties of the alloy are changed. Therefore, the surface quality is good, the finish is high, the dimensional precision of the product is high, and the performance and organization of the product can meet some special requirements, such as electromagnetic properties and deep drawing properties. Cold-rolled strip can be used in automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, food canning, etc.