Welcome to Shandong Zhishang Steel Co., Ltd.

Get a free quote quickly!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec id erat sagittis, faucibus metus malesuada, eleifend turpis. Mauris semper augue id nisl aliquet, a porta lectus mattis. Nulla at tortor augue. In eget enim diam. Donec gravida tortor sem, ac fermentum nibh rutrum sit amet. Nulla convallis mauris vitae congue consequat. Donec interdum nunc purus, vitae vulputate arcu fringilla quis. Vivamus iaculis euismod dui.

There are two kinds: air-cooled and water-cooled.

There are three kinds of vertical, horizontal and vertical annealing furnaces.

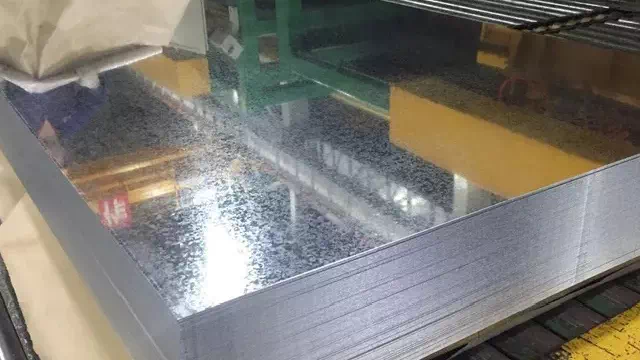

Product categories: General coil (CQ), structural galvanized sheet (HSLA), deep drawing hot galvanized sheet (DDQ), baking and hardening hot galvanized sheet (BH), duplex steel (DP), TRIP steel (Phase change induced plastic steel), etc.

It can be divided into two types of in-line annealing and out-of-line annealing, which are also called protective gas method and flux method.

There are three types of electrogalvanizing, hot-dip galvanizing and coating galvanizing.

Hot galvanized sheet is mainly used in construction, home appliances, automobiles, machinery, electronics, light industry and other industries

Specification and thickness of galvanized sheet

The thickness of ordinary galvanized sheet is 0.4~2.0.

Generally, it is not produced by large steel mills of state-owned enterprises, but by small steel mills of private enterprises. Conventional specifications are 0.35, 0.30, 0.28, 0.25, the thinest is generally 0.1, more than 2.0mm, because straightening is very difficult, the price above 2.0 will increase with the increase of thickness.

There are two kinds of galvanized sheet: hot galvanized sheet and electrogalvanized sheet. The national standards of these two kinds of galvanized sheets are briefly introduced.

According to GB/T 2518-2008, the thickness range of hot galvanized sheet is 0.3 ~ 5.0 mm

According to GB/T 15675-2008 "Continuous electric galvanized, zinc-nickel alloy coated steel plate and steel strip", its plate thickness is not specified. But according to GB/T 708-2006 "cold rolled steel plate and strip size, shape, weight and allowable deviation", galvanized sheet thickness is 0.40 ~ 4.00 mm

What kind of materials are used in different kinds of galvanized steel?

1. hot dip galvanized steel plate. The sheet steel is dipped into the melted zinc tank so that the surface is adhered to a zinc sheet steel. At present, continuous galvanizing process is mainly used to produce, that is, continuous immersion of rolled steel plate in the melting of zinc in the plating tank to make galvanized steel plate;

2. alloyed galvanized steel plate. This steel plate is also made by hot dipping, but immediately after it is out of the groove, it is heated to about 500℃ to create an alloy coating of zinc and iron. This galvanized sheet has good coating tightness and weldability;

3. electric galvanized steel plate. The galvanized steel plate made by electroplating has good workability. But the coating is thin, corrosion resistance is not as good as hot dip galvanized sheet;

4. single-side plating and double-side difference galvanized steel plate. Single-sided galvanized steel plate, that is, galvanized products only on one side. It has better adaptability than double-sided galvanized sheet in welding, coating, rust prevention and processing. In order to overcome the shortcomings of single side without zinc coating, there is a galvanized sheet coated with a thin layer of zinc on the other side, namely double-sided differential galvanized sheet;

5. alloy, composite galvanized steel plate. It is made of zinc and other metals such as lead, zinc alloy or composite plating of steel plate. This kind of steel plate not only has excellent anti-rust performance, but also has good coating performance.

H section steel is a new type of economical building steel. It is an economic cross-section steel with good mechanical properties, which is optimized and developed for I-beam steel. It is named because its section is the same as the English letter "H".

The main features are as follows:

1. high structural strength: compared with I-steel section modulus is large, under the same bearing conditions can save metal 10-15%.

2. Flexible and rich design style: in the case of the same beam height, the steel structure can be 50% larger than the concrete structure, so that the building layout is more flexible.

3. high structural stability: the steel structure is dominated by hot rolled H-beam steel, scientific and reasonable structure, good plasticity and flexibility, high structural stability. Especially suitable for some earthquake prone areas of the building structure.

4. increase the effective use area: compared with concrete structure, steel structure column cross-sectional area is small, can increase the effective use area of the building. Depending on the building form, the effective use area can be increased by 4-6%.

5. easy processing: easy structural connection and installation, but also easy to disassemble and reuse.

6. High degree of industrial production: The steel structure based on hot rolled H beam has a high degree of industrial production, which is convenient for mechanical manufacturing, intensive production, high precision, convenient installation and easy quality assurance. You can build real house manufacturing plants, bridge manufacturing plants, industrial plants, manufacturing plants, etc.

7. the construction speed is fast: covers an area of small, suitable for all-weather construction, the influence of climate conditions is small. The construction speed of hot rolled H-beam steel structure is about 2-3 times that of concrete structure, and the capital turnover rate is doubled, which reduces the financial cost and saves investment.

Galvanizing is the process of adding a layer of zinc to the outer surface of a metal. The idea is to add a protective coating to the underlying metal, reducing the likelihood of corrosion or rust.

Galvanizing process varies with specific technology. However, the most important part of the process is that it usually involves enclosing steel or iron in zinc, which may be in a liquid or dust-like state. When zinc is introduced, the iron in the surrounding metal reacts with the zinc to form a tightly bonded alloy coating.

The popularization and application of high-precision cold-drawn precision steel pipe is to save steel, improve processing efficiency and save energy. The so-called high-precision cold-drawn seamless steel pipe refers to the strict inner and outer diameter dimensional accuracy (tolerance range), and the internal and external surface finish, roundness and straightness are good, which can greatly save machining hours, improve the utilization rate of materials, and help to improve product quality.

High precision cold-drawn steel pipe is a new type of steel pipe, its main characteristic is high precision. Usually there are two production processes of two-high rolling mill and three-high rolling mill. The precision of cold-rolled seamless steel pipe produced by three-high rolling mill is higher, which can be controlled within a few wires, but the price is relatively higher.

The reason why sheet metal chassis processing uses galvanized tin plating

Now sheet metal chassis, generally with galvanized steel plate manufacturing. The reason why the steel plate is galvanized is mainly for corrosion protection. But because zinc is not easy to oxidize metal, so galvanized steel can be isolated from the air, to achieve the purpose of corrosion prevention, this understanding is wrong; In fact, the opposite is true. Zinc is a very reactive metal that is easily oxidized. But instead of being a loose powder like iron oxide, zinc oxide is a dense surface, and this layer of zinc oxide prevents further oxidation of the zinc inside.

For sheet metal case processing When the surface of galvanized steel plate is damaged and exposed to the internal iron surface, according to the principle of chemical batteries, zinc will oxidize before iron to protect the iron layer from damage because zinc is more active than iron. The combination of the two is the truth of galvanized steel plate protection. A good galvanized steel sheet should be grey and white matte, which is the color of the zinc oxide surface.

Some chassis of poor material use poor quality galvanized steel, even tinned steel plate. The product generally has a thin, uneven coating. Especially tinned steel, if the tin layer is not damaged, everything will be fine. However, once the tin layer is damaged, the iron will become the protection of the tin, rather than the pure steel plate paint, because tin is an inert metal.

The function and technology of galvanized steel plate

The role of galvanized steel

Galvanized steel is one of the most widely used materials in construction and manufacturing. It is strong and resistant to corrosion, while being relatively inexpensive, making it ideal for many different applications. But what exactly is galvanized steel and what does it do? In this blog post, we will explore the properties, uses and importance of galvanized steel in modern construction and manufacturing. We'll also learn how the material has evolved over time and how it continues to be a major player in the industry.

What is galvanized steel?

Galvanized steel is a type of steel coated with zinc. The coating helps protect the steel from corrosion and rust. Galvanized steel is commonly used in construction, especially for projects that will be exposed to the elements.

Electroplating process

Galvanizing process is simple and effective. It involves dipping clean steel into molten zinc. The zinc binds to the steel and forms a protective layer against corrosion. The process can be used on small and large steels, making it a versatile option for protecting metals from corrosion.